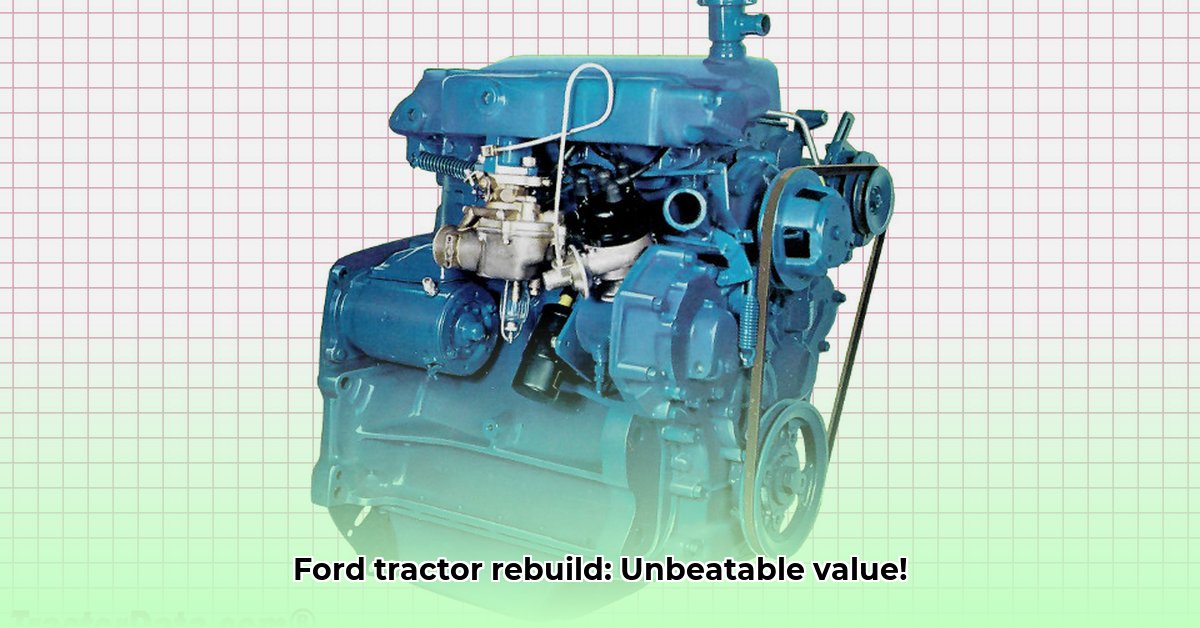

The agricultural landscape demands reliable machinery, and for many, that means a well-maintained Ford tractor. Engine failure, however, can bring operations to a standstill. While a brand-new engine represents a significant investment, a rebuilt Ford tractor motor offers a compelling alternative—delivering high-quality performance at a fraction of the cost. This comprehensive guide explores the rebuilt Ford tractor engine market, providing the actionable intelligence needed to make informed decisions. For detailed Ford tractor information, check out these free manuals.

Understanding the Rebuilt Ford Tractor Engine Market

Demand for rebuilt Ford tractor engines is surging. Why? Older Ford tractors are renowned for their robust construction and longevity. Repairing these durable engines frequently proves more cost-effective than purchasing a new one, driving market growth. While precise market figures remain elusive, the substantial volume of rebuilt engines listed on online marketplaces reveals a significant and active market. However, supply fluctuates, emphasizing the need for informed planning and proactive sourcing. Is the current market surplus or shortage a factor in your purchasing strategy?

Cost Comparison: New vs. Rebuilt Ford Tractor Engines

Financial considerations are paramount. A rebuilt engine offers substantial savings compared to a new one. This cost-benefit analysis considers initial purchase price, warranty duration, core return value (credit for your old engine), and projected long-term maintenance expenses. The following table provides a general comparison; actual costs vary by engine model, supplier, and location.

| Feature | New Engine | Rebuilt Engine |

|---|---|---|

| Initial Purchase Price | Significantly Higher | Significantly Lower |

| Warranty Period | Typically Shorter (1-2 years) | Varies (Potentially Longer) |

| Core Return Value | Usually None | Often Provides Substantial Credit |

| Long-Term Maintenance | Potentially Lower Initially | Potentially Higher Over Time |

The initial price difference is substantial. However, a well-maintained rebuilt engine can provide years of reliable service, potentially offsetting long-term maintenance costs.

Quality and Reliability: Rebuilt vs. Remanufactured

Understanding the distinction between "rebuilt" and "remanufactured" is crucial. A rebuilt engine involves repairing and replacing worn components. A remanufactured engine undergoes a more extensive process, often exceeding original specifications. It's analogous to a tune-up versus a complete restoration. Always inquire about the remanufacturing process, certifications, and warranty details. Independent inspections offer peace of mind, particularly for high-value purchases. What level of assurance do you require from your supplier?

Finding and Buying Your Rebuilt Ford Tractor Engine: A Practical Guide

- Thorough Research: Identify reputable suppliers using online reviews and industry recommendations. Consider those specializing in Ford tractor engines.

- Spec Verification: Carefully verify engine specifications (horsepower, model number, etc.) to ensure precise compatibility. Incompatibility can lead to future problems. Will you engage an expert to verify the specification?

- Warranty Scrutiny: Meticulously examine warranty terms, coverage duration, and any exclusions. A comprehensive warranty often indicates higher quality. Are the warranty terms sufficient to cover potential repairs?

- Price Negotiation: Research market pricing and don't hesitate to negotiate favorably. What is your target price point?

- Logistics and Installation: Plan for engine transportation and installation, including potential labor costs. Will you handle installation yourself or outsource it?

Maintaining Your Rebuilt Engine for Maximum Lifespan

Proactive maintenance is essential for extending engine life. Consistent oil changes, regular filter replacements (oil, air, fuel), and timely coolant flushes are vital. Consult your tractor's owner's manual for recommended intervals. Neglecting maintenance accelerates wear and increases the likelihood of costly repairs. What preventative maintenance schedule will you implement?

Regulatory Compliance: Emission and Waste Disposal

Compliance with local and national emission and waste disposal regulations is crucial. Familiarize yourself with these standards before purchasing or disposing of your engine. Non-compliance can incur significant penalties. Have you consulted the relevant regulatory authorities in your area?

Conclusion: A Responsible and Cost-Effective Solution

Rebuilt Ford tractor engines offer a compelling combination of cost-effectiveness and environmental responsibility. They provide a viable alternative to purchasing a new engine, extending the lifespan of existing tractors and reducing agricultural waste. By carefully selecting a reputable supplier, understanding engine types, and adhering to a robust maintenance schedule, farmers and equipment owners can ensure a successful and cost-effective solution. Are you prepared to implement these strategies for maximizing the lifespan of your rebuilt engine?